charpy impact test subject dimensions inches|charpy impact test specimen : retailer The standard Charpy impact test specimen is of dimension 55 mm × 10 mm × 10 mm, having a notch machined across one of the larger dimensions, as illustrated in Fig. 1.3. The Charpy . A história do físico americano Julius Robert Oppenheimer e seu papel no Projeto Manhattan e no desenvolvimento da bomba atômica durante a Segunda Guerra .

{plog:ftitle_list}

WEBXloveCam® is a free live webcam platform on which more than 100,000 sexy live girls have registered themselves for a hard or soft sexy live show of your choice. On the high .

CHARPY IMPACT TEST ISO 179. Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic .

The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and .

Charpy specimens of five different geometries were tested: • full-size Charpy V-notch specimens (CVN); • sub-size Charpy V-notch specimens (SCVN) with thicknesses B = 7.5 mm (3/4-size), .

3.1.2 For material under 10 mm in thickness, the largest possible size of standard subsidiary Charpy V-notch test specimen is to be prepared with the notch cut on the narrow face. .The standard Charpy impact test specimen is of dimension 55 mm × 10 mm × 10 mm, having a notch machined across one of the larger dimensions, as illustrated in Fig. 1.3. The Charpy .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .

Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm. The notch .the production of reference Charpy specimens for the indirect verification of impact testing machines in accordance with ASTM E23-12c: two quenched and tempered 4340 steels (with different mechanical properties . • sub-size Charpy V-notch specimens (SCVN) with thicknesses B = 7.5 mm (3/4-size), 5 mm (1/2-size), and 2.5

adjustment of sub-size Charpy-V specimen . KV/(Bb) [J/cm. 2] T [o. C] McNicol 1965. McNicol, R. (1965, September). Correlation of Charpy Test Results for Standard and Nonstandard Size Specimens. Welding Research Supplement, pp. 385-393. . Impact Characterization of Line Pipe Steels by Means of Standard, Sub-Size and Miniaturized Charpy .Many notched bar impact tests of different designs and loading have been used to predict brittle fracture of ferritic steels. In the USA, the Charpy specimen has been standardized in ASTM E23 for impact three-point bend testing (ASTM E23 1999).Figure 1 illustrates a standard ASTM type A Charpy impact test specimen. The Charpy three-point bend specimen is more convenient .standard, full-size Charpy specimens (CVN) and specimens with reduced thickness (sub-size Charpy specimens, SCVN) or reduced or scaled cross-section dimensions (miniaturized Charpy specimens, MCVN). A database of instrumented impact test results was generated from four line pipe steels, two quenched

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.CHARPY IMPACT TESTING IZOD IMPACT TESTING Tested Materials Plastics Plastics Types of Notches (0.25mm) Preferred V-notch V-notch . The ASTM uses a specimen that is ½ inch wide and can be either 1/8 or 1/4 inches thick. The ISO method uses a specimen that is 10 . condition and test the specimens using the size, dimensions and test method .The ductile to brittle transition with decreasing temperature has been investigated by Charpy impact test with sub-size specimen for the ferrite + pearlite structure steel sheet.

Fully Automatic Seal Tester trading

Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. . Specimen size: Specimens are 80 x 10mm by thickness. The specimens can be either notched or unnotched . The Charpy test results are affected by many factors, such as the state of the specimen (size, notch type, notch depth, etc.), the state of the impact testing machine (stiffness, hammer radius .

Charpy Impact Test. In a Charpy test, a notched specimen is struck by a pendulum hammer swinging from a known height. The energy absorbed by the specimen during fracture is calculated by the difference in the pendulum’s height before and after impact. This energy absorption measures material toughness.

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.

Semi-Automatic Seal Tester trading

Download scientific diagram | Size and orientation of the Charpy impact test specimens with respect to the rolled plate. from publication: A review on the effect of microstructure, texture and . An Izod impact testing apparatus — which is essentially identical to a Charpy impact testing machine — is used to determine Izod impact strength. The primary differences between the Izod and Charpy impact tests are the size of the test specimen, how it is restrained, and which side is struck by the pendulum hammer.Charpy Impact Testing Sub-Size Specimens to ASTM E23, A370 and ISO 148-1. ASTM E23 and ISO 148-1 define test methods for Charpy impact testing of notched-bar metallic specimens. ASTM A370 also includes Charpy impact test method requirements but focuses only on steel products. All three standards provide details for properly measuring the energy . Charpy impact test is a comparative style test used to define a material’s impact strength. Learn more about it here. . Prepare Samples: The samples must be prepared with dimensions according to the relevant .

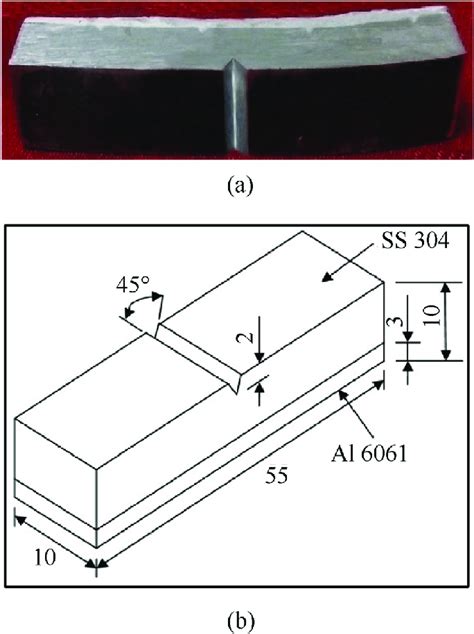

Energy absorbed was taken directly from each test, and impact energy was calculated by dividing the energy absorbed by the cross-sectional area of the unnotched ligament: 0.8 and 0.6 cm 2 for the . The standard size of a specimen for Charpy impact testing is 10 mm × 10 mm × 55 mm. A 2mm deep notch with an angle of 45° and a tip radius of 0.25mm is then machined into one face of the bar. These specifications have a very tight tolerance because the shape and size of the notch can have a significant effect on the results of the test.S91.1 The steel shall be killed with a fine austenitic grain size. SX3. Charpy V-Notch Impact Test for Group 4 and 5 Structural Shapes SX3.1 When Group 4 and 5 structural shapes are used as members subject to primary tensile stress and when such members are spliced using full penetration welds, the steel shall be impact tested in accordance withThis study examines the use of small steel pieces regarded as cores, which are taken from stop-holes or bolt-holes. Test specimens for Charpy impact test are made with small steel pieces by Electron Beam Weld (EBW) and the effect of the steel piece size and the other parameters on Charpy absorbed energy are examined.

charpy test sample dimensions

The correlation of microstructure and Charpy V-notch (CVN) impact properties of a high-toughness API X70 pipeline steel was investigated in this study. The normal standard size for a Charpy impact test specimen is a 10mm by 10mm by 55mm long specimen for ISO 148 and ASTM E23/ASTM A370 standards. However, not all test pieces allow for the standard size to be machined and therefore a sub-sized specimens must be extracted to achieve impact properties.

The full size and miniaturized Charpy impact test speci-mens were prepared in which axis of the specimens corre-sponds to the rolling direction. The size of the full size speci-men was 10 10 55mm. The miniaturized specimens were of four different sizes: 3:3 3:3 23:6mm, 2:0 2:0 20mm,asymmetrical fracture, indirect verification Charpy specimens, shear lips, sample size, side-grooving, symmetrical fracture Introduction Charpy impact testing is a low-cost and reliable test method for measuring the impact resistance of materials and is commonly required by construction codes for fracture-critical structures and pressure vessels. A total of 7 specimens for Charpy impact test were obtained by cutting each composite plates according to ASTM D6110 dimensions [28]. The tests were performed in a PANTEC instrumented pendulum, Model XC-50, 1 × 220 V × 60 Hz.CVNx Charpy V-Notch specimen of non standard width x Key words: Impact loading, high strain-rate, adiabatic heating, ductile-brittle transition 1. Introduction The absorbed energy versus temperature or strain rate in the Charpy V-notch test is often used to characterize the ductile-to-brittle transition in steels. Brittle fracture is found at .

5.3 For this test method, the energy lost by the pendulum during the breakage of the specimen is the sum of the energies required to initiate fracture of the specimen; to propagate the fracture across the specimen; to throw the free ends of the broken specimen (toss energy); to bend the specimen; to produce vibration in the pendulum arm; to produce vibration or .

charpy impact test standard pdf

Touchscreen Fully Intelligent Seal Tester (Vacuum Pump Model) trading

webNovinha Branquinha Dançando Funk de Fio Dental. 73 sec Xmichael Myers -. Novinha branquinha gemendo gostoso. 12 min Miranda098123 -. 720p. Branquinha novinha .

charpy impact test subject dimensions inches|charpy impact test specimen